ASME B 16.5-2003 CLASS 150 | |||||||||||||

CLASS 150 | FLANGE THICKNESS | LTB | DRILLINE DATA | CLASS 150 | |||||||||

NOMINAL | FLANGE | THICKNESS | THICKNESS | BOSSED | WELD | LAP JOINT | LONG | PITCH | BOLT | NUMBER | NOMINAL | ||

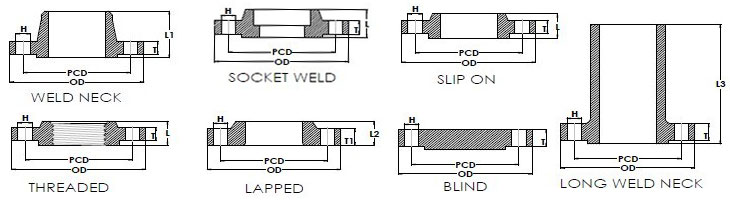

MM | INCH | OD | T | T1 | L | L1 | L2 | L3 | PCD | H | # | MM | INCH |

15 | 1/2 | 90 | 9.6 | 11.2 | 16 | 46 | 16 | 229 | 60.3 | 16 | 4 | 15 | 1/2 |

20 | 3/4 | 100 | 11.2 | 12.8 | 16 | 51 | 16 | 229 | 69.9 | 16 | 4 | 20 | 3/4 |

25 | 1 | 110 | 12.7 | 14.3 | 18 | 54 | 18 | 229 | 79.4 | 16 | 4 | 25 | 1 |

32 | 1 1/4 | 115 | 14.3 | 15.9 | 21 | 56 | 21 | 229 | 88.9 | 16 | 4 | 32 | 1 1/4 |

40 | 1 1/2 | 125 | 15.9 | 17.5 | 22 | 60 | 23 | 229 | 98.4 | 16 | 4 | 40 | 1 1/2 |

50 | 2 | 150 | 17.5 | 19.1 | 25 | 62 | 26 | 229 | 120.7 | 20 | 4 | 50 | 2 |

65 | 2 1/2 | 180 | 20.7 | 22.3 | 29 | 68 | 29 | 229 | 139.7 | 20 | 4 | 65 | 2 1/2 |

80 | 3 | 190 | 22.3 | 23.9 | 30 | 68 | 31 | 229 | 152.4 | 20 | 4 | 80 | 3 |

90 | 3 1/2 | 215 | 22.3 | 23.9 | 32 | 70 | 32 | 229 | 177.8 | 20 | 8 | 90 | 3 1/2 |

100 | 4 | 230 | 22.3 | 23.9 | 33 | 75 | 34 | 229 | 190.5 | 20 | 8 | 100 | 4 |

125 | 5 | 255 | 22.3 | 23.9 | 36 | 87 | 37 | 305 | 215.9 | 23 | 8 | 125 | 5 |

150 | 6 | 280 | 23.9 | 25.5 | 40 | 87 | 40 | 305 | 241.3 | 23 | 8 | 150 | 6 |

200 | 8 | 345 | 27 | 28.6 | 44 | 100 | 45 | 305 | 298.5 | 23 | 8 | 200 | 8 |

250 | 10 | 405 | 28.6 | 30.2 | 49 | 100 | 50 | 305 | 362 | 26 | 12 | 250 | 10 |

300 | 12 | 485 | 30.2 | 31.8 | 56 | 113 | 56 | 305 | 431.8 | 26 | 12 | 300 | 12 |

350 | 14 | 535 | 33.4 | 35 | 58 | 125 | 79 | 305 | 476.3 | 29 | 12 | 350 | 14 |

400 | 16 | 595 | 35 | 36.6 | 64 | 125 | 87 | 305 | 539.8 | 29 | 16 | 400 | 16 |

450 | 18 | 635 | 38.1 | 39.7 | 69 | 138 | 97 | 305 | 577.9 | 32 | 16 | 450 | 18 |

500 | 20 | 700 | 41.3 | 42.9 | 73 | 143 | 103 | 305 | 635 | 32 | 20 | 500 | 20 |

600 | 24 | 815 | 46.1 | 47.7 | 82 | 151 | 111 | 305 | 749.3 | 35 | 20 | 600 | 24 |

NOTES: *Schedule of weld neck to be indicated. | |||||||||||||

0 comments:

Post a Comment