AS 2129:2000 TABLE E | ||||||||||

TABLE E | LENGTH THROUGH HUB | DRILLING DATA | TABLE E | |||||||

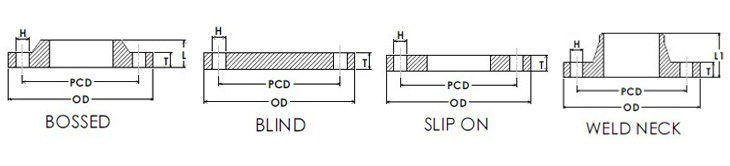

NOMINAL | FLANGE | THICKNESS | BOSSED | WELD | PITCH | BOLT | NUMBER | NOMINAL | ||

MM | INCH | OD | T | L | L1 | PCD | H | ﹟ | MM | INCH |

15 | 1/2 | 95 | 6 | 16 | 28 | 67 | 14 | 4 | 15 | 1/2 |

20 | 3/4 | 100 | 6 | 17 | 28 | 73 | 14 | 4 | 20 | 3/4 |

25 | 1 | 115 | 7 | 18 | 29 | 83 | 14 | 4 | 25 | 1 |

32 | 1 1/4 | 120 | 8 | 19 | 33 | 87 | 14 | 4 | 32 | 1 1/4 |

40 | 1 1/2 | 135 | 9 | 22 | 38 | 98 | 14 | 4 | 40 | 1 1/2 |

50 | 2 | 150 | 10 | 23 | 39 | 114 | 18 | 4 | 50 | 2 |

65 | 2 1/2 | 165 | 10 | 26 | 42 | 127 | 18 | 4 | 65 | 2 1/2 |

80 | 3 | 185 | 11 | 27 | 46 | 146 | 18 | 4 | 80 | 3 |

90 | 3 1/2 | 205 | 12 | 29 | 47 | 165 | 18 | 8 | 90 | 3 1/2 |

100 | 4 | 215 | 13 | 32 | 54 | 178 | 18 | 8 | 100 | 4 |

125 | 5 | 255 | 14 | 33 | 58 | 210 | 18 | 8 | 125 | 5 |

150 | 6 | 280 | 17 | 36 | 65 | 235 | 22 | 8 | 150 | 6 |

200 | 8 | 335 | 19 | 41 | 70 | 292 | 22 | 8 | 200 | 8 |

225 | 9 | 370 | 21 | 46 | 78 | 324 | 22 | 12 | 225 | 9 |

250 | 10 | 405 | 22 | 49 | 86 | 356 | 22 | 12 | 250 | 10 |

300 | 12 | 455 | 25 | 54 | 95 | 406 | 26 | 12 | 300 | 12 |

350 | 14 | 525 | 29 | 102 | 470 | 26 | 12 | 350 | 14 | |

375 | 15 | 550 | 32 | 108 | 495 | 26 | 12 | 375 | 15 | |

400 | 16 | 580 | 32 | 521 | 26 | 12 | 400 | 16 | ||

450 | 18 | 640 | 35 | 584 | 26 | 16 | 450 | 18 | ||

500 | 20 | 705 | 38 | 641 | 26 | 16 | 500 | 20 | ||

525 | 21 | 735 | 41 | 673 | 30 | 16 | 525 | 21 | ||

550 | 22 | 760 | 44 | 699 | 30 | 16 | 550 | 22 | ||

600 | 24 | 825 | 48 | 756 | 33 | 16 | 600 | 24 | ||

700 | 28 | 910 | 51 | 845 | 33 | 20 | 700 | 28 | ||

750 | 30 | 995 | 54 | 927 | 36 | 20 | 750 | 30 | ||

800 | 32 | 1060 | 54 | 984 | 36 | 20 | 800 | 32 | ||

850 | 34 | 1090 | 57 | 1016 | 36 | 20 | 850 | 34 | ||

900 | 36 | 1175 | 64 | 1092 | 36 | 24 | 900 | 36 | ||

1000 | 40 | 1255 | 67 | 1175 | 39 | 24 | 1000 | 40 | ||

1050 | 42 | 1335 | 70 | 1251 | 39 | 28 | 1050 | 42 | ||

1200 | 48 | 1490 | 79 | 1410 | 39 | 32 | 1200 | 48 | ||

NOTES: (1) The minimum flange thickness in carbon steel flanges will be 12mm. (4) For special requirement, please make a enquiry here now. | ||||||||||

0 comments:

Post a Comment